We offer customized solutions for manual transfer of flat bottomed loads. The transfers can be done either by manual pushing by operator or by using height differential under the force of gravity. Most manual conveyors utilise different types of rollers for achieving the desired movement of the load. We use a variety of rollers depending on the dimension and weight of the loads to be conveyed. Most common types are as listed below.

• Steel Rollers

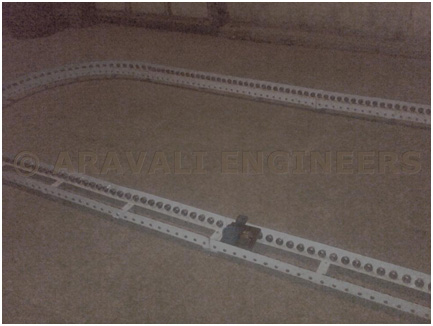

• Roller Placons Consisting of Plastic Rollers in GI Profile

• Guided Rollers

• Roller Balls (Ball Caster Units)

The frame construction is also customized based on the application and aesthetic considerations. Common materials of construction are MS tubular sections, Extruded Aluminium Sections, ABS Coated (Goblin) Pipes.

Most common structures utilizing manual conveying are assembly lines, FIFO storage, truck loading/unloading operations, inter floor transfer and other similar applications. These conveyors can also incorporate pneumatic push up turn tables for up to 360 degree rotation of units. For closed loop conveying transfer units consisting of ball caster tables can be used. Similarly for inter floor transfer spiral gravity roller conveyors can be used.

Optional Accessories for manual assembly lines: illumination, electrical sockets, display board, centre platform, end stopper, tool hanger, screw channel, bin hanger, air pipeline with QRC, rejection chutes and bin stands.

Please send us your detailed requirements to get customized quotes for the best solution for your requirement.